Instrumentation and Methods

Experimental Systems:

The group operates cutting-edge instruments and develops new experimental solutions that bridge between ideal ultraclean environments and true operation conditions (high-pressure, solid/liquid, electrochemical, photoelectrochemical environments). Some of the infrastructure is listed below.

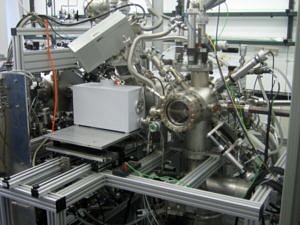

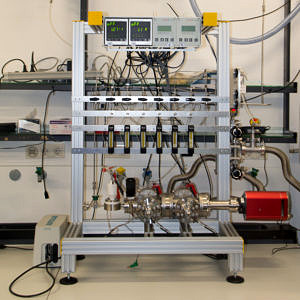

We operate a molecular beam / spectroscopy / reactor experiment, which allows performing complex kinetic experiments in a quantitative, reproducible and fully remote-controlled fashion. Among other facilities, the system includes:

- Pulsed / chopped supersonic molecular beam source

- Four modulated effusive beam sources

- Vacuum-FT-IR-spectrometer for time resolved surface IR spectroscopy (TR-IRAS) (Bruker Vertex 80v)

- In-situ UV photochemistry in UHV

- Fast ion-counting quadrupole mass spectrometer (QMS) w. multichannel scaling

- Fast TR-IRAS-compatible pressure gap reactor

- High-pressure cell for polarization-dependent TR-IRAS

- Various preparation and characterization techniques for model surfaces (TPD, LEED, AES, etc.)

- Vacuum sample transfer system

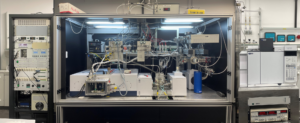

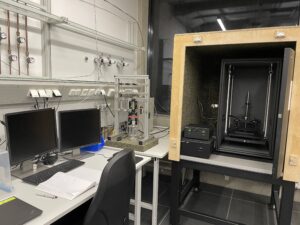

A home-built operando spectroscopy system allows studying catalytic reactions on single-crystal based model catalysts, porous materials and films, powders, ionic liquid films, heterogeneous and homogeneous catalysts and related materials.

The key features of the system include:

- IRAS (IR Reflection Absorption Spectroscopy) (Bruker Vertex 80v)

- TR-IRAS (Time Resolved IR Spectroscopy, including Step Scan FTIR and Rapid Scan FTIR)

- PM-IRAS (Polarization Modulation IRAS)

- TIRS (Transmission IR Spectroscopy)

- DRIFTS (Diffuse Reflection IR FT Spectroscopy)

- Transient and Stationary Experiments (Pulse Gas Dosing and Laser Heating)

- Real-Time Mass Spectrometry

- Online High Sensitivity Gas Chromatography

- Vacuum Transfer of UHV-Prepared Model Catalysts

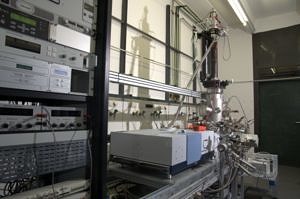

The key features include:

- Vacuum-FT-IR-spectrometer for time resolved surface IR spectroscopy (TR-IRAS) (Bruker Vertex 80v)

- Combined IR spectroscopy in the FIR and MIR region (automatic beamsplitter changer)

- Two remote-controlled gas dosers for adsorption studies

- Two metal evaporator sources in IR measurement position

- Two IL/organic evaporator sources in IR measurement position

- TPD in IR measurement position

- Four modulated effusive beam sources

- Various preparation and characterization techniques for model surfaces (TPD, LEED, AES, etc.)

- Vacuum sample transfer system

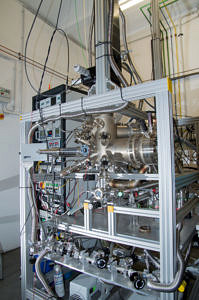

The IR spectroelectrochemistry system allows in-situ studies at electrified interfaces, both on real materials and on ideal model surface. The system is designed for sample transfer under controlled conditions and is designed for various electrochemical characterization methods, including in-situ and time resolved photoelectrochemical studies.

The key features include:

- High-end vacuum-FT-IR-spectrometer (Bruker Vertex 80v)

- IR optics for fixed and variable angle

- Time resolved interfacial IR spectroscopy (rapid scan and step scan)

- Home-built electrochemical cells for IR spectroscopy in external reflection and in ATR

- Spectroelectrochemistry in internal and external reflection (EC-IRRAS, SNIFTIRS, LPSIRS, SEIRAS)

- Gas supply system for electrocatalytic studies (e.g. fuel cell, electrolysers, electrosynthesis)

- Electrochemical characterization methods (cyclic voltammetry, electrochemical impedance spectroscopy)

- Single crystal electrochemistry and characterization

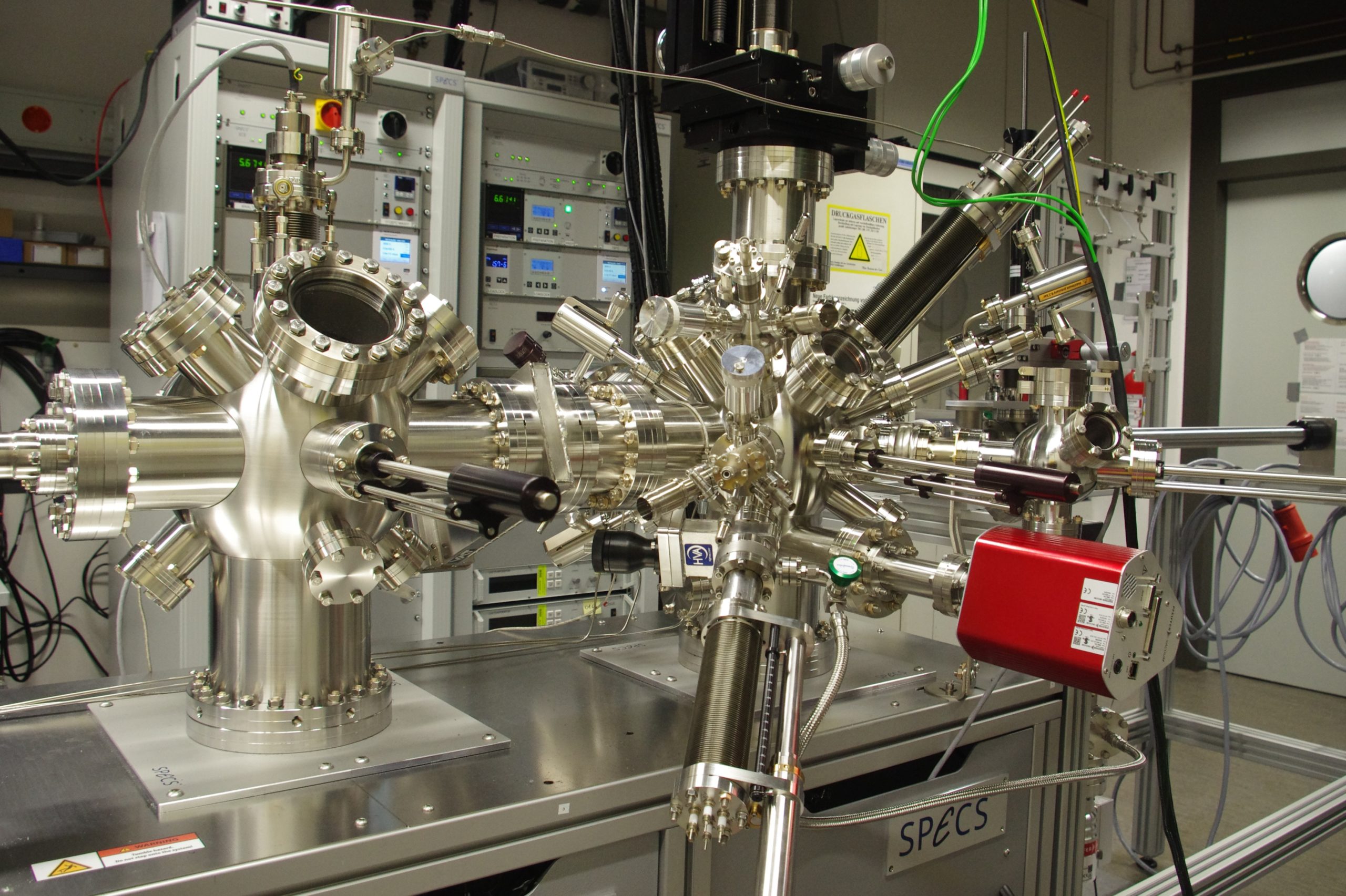

The key features include:

- UHV system with sample preparation (e.g. PVD) and characterization facilities (LEED, AES, TPD, etc.)

- Sample transfer system (vacuum/protective gas)

- Electrochemical characterization techniques: cyclic voltammetry (CV), electrochemical impedance spectroscopy (EIS)

- Direct transfer to electrochemical IR spectroscopy (EC-IRRAS), differential electrochemical mass spectrometry (DEMS), electrochemical atomic force microscopy (EC-AFM), electrochemical scanning tunneling microscopy (EC-STM)

The key features include:

- Double differentially pumped UHV system with QMS

- Differential electrochemical mass spectrometry (DEMS) in thin-film configuration

- Online electrochemical mass spectrometry (OLEMS) with microfluidic probe for planar model electrodes (Spectro Inlets)

The key features include:

- Electrochemical atomic force microscopy (EC-AFM) (Keysight AFM/SPM Series 5500)

- Electrochemical scanning tunneling microscopy (EC-STM) (Keysight STM/AFM Series 5500)

- Sample transfer environment from UHV

- Controlled gas environment and supply system

- EC-STM tip preparation

The new UHV Scanning Tunneling Microscope / Atomic Force Microscope allows us to perform structural characterization of model interfaces with atomic resolution. It is equipped with an electrochemical cell for immersion/emersion experiments without contact to ambient conditions.

The key features include:

- Variable temperature scanning tunneling microscopy in UHV (Specs SPM Aarhus HT)

- Variable temperature atomic force microscopy in UHV

- Transfer system with electrochemical cell

- Sample transfer system

- Preparation tools for complex model interfaces

The new Atomic Force Microscope allows us to perform structural characterization of solid interfaces in a controlled environment. In particular, we can perform in situ measurements in liquids and under electrochemical conditions.

The key features include:

- Electrochemical atomic force microscopy (EC-AFM) (Oxford Instruments Cypher ES)

- Acquisition of force curves

- Temperature control (0-250°C)

- Controlled gas environment

- Perfusion cell (liquid / gas), liquid drop cell (including electrochemical control) and heating/cooling sample stage (gas) accessory

- Fast scanning mode

- photothermal excitation (blueDrive™) of AFM tip